Rope pumps & irrigation

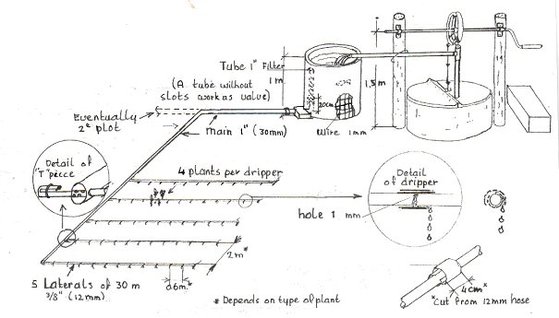

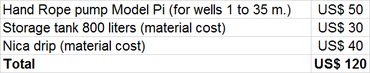

An example: Irrigating 1000 tomato plants for US$ 120 Including: Pump, storage, irrigation system.

Rope pump

The pump capacity of a Hand Rope pump from a 10m. deep well is 2.4 m3/hour Pumping ½ hour in the morning and evening gives water to irrigate 1000 tomato plants. The Rope pump Pi model, can directly fill a water storage tank.

Storage tank made of cement

Instead of a metal drum, a cement tank may be used with the advantage of lower cost and no corrosion. The volume can be 500 to ..5000 liters, the lower part can be used for some fish production, and the tank can be constructed with local materials and skills. After a short training, users can make the tank themselves. The tank is round and reinforced with steel wire on the outside of the bricks. The filter for the outlet can be made out of PVC tubing. Instead of an outlet valve, PVC caps or tubes can be used

A cement tank of 800 liters consists of:

100 bricks, 1 kg of 1mm steel wire, 2 bags of cement, 6 bags of sand.

Nica-drip system

A water level in the tank of 0.5 meter is enough for the Nica-drip to function. A system to irrigate 1000 tomato plants consist of:

Costs (based on cost in Nicaragua)

The pump capacity of a Hand Rope pump from a 10m. deep well is 2.4 m3/hour Pumping ½ hour in the morning and evening gives water to irrigate 1000 tomato plants. The Rope pump Pi model, can directly fill a water storage tank.

Storage tank made of cement

Instead of a metal drum, a cement tank may be used with the advantage of lower cost and no corrosion. The volume can be 500 to ..5000 liters, the lower part can be used for some fish production, and the tank can be constructed with local materials and skills. After a short training, users can make the tank themselves. The tank is round and reinforced with steel wire on the outside of the bricks. The filter for the outlet can be made out of PVC tubing. Instead of an outlet valve, PVC caps or tubes can be used

A cement tank of 800 liters consists of:

100 bricks, 1 kg of 1mm steel wire, 2 bags of cement, 6 bags of sand.

Nica-drip system

A water level in the tank of 0.5 meter is enough for the Nica-drip to function. A system to irrigate 1000 tomato plants consist of:

- 10 laterals of 30 m long with 1 mm holes at intervals of 0.3 meter

(laterals are ½ inch hose, 15 mm inside, and made of black plastic) - 1 Submain of 15 meter with 19 mm holes at intervals of 1 meter

(submain are 1 ½ Inch hose 400 mm inside, and made of black plastic)

Costs (based on cost in Nicaragua)

Example: Burkina Faso

|

With a pedal powered Rope pump some 300 m2 is irrigated with Drip irrigation. The system consists of KB drip laterals with pre punched holes and locally produced PVC pipe or poly pipe. The outlet of the pump is directly coupled to the drip systems. No need for a water tank. The total height of the outlet pipe is 80- 90cm high. The outlet nipple functions as a pressure equaliser. Water level high more water pressure so more water for the drip outlet

Compared to an irrigation system with an elevated tank:

|

|

Increase world food production

with

Low-cost irrigation technology for small farmers

The green revolution has tripled world grain production using fertilizers and irrigation but has now come to limits like availability of water, salinity, unsustainable mechanization, energy consumption, etc. 1 Billion people still experience hunger and the world population is growing, so new approaches and technologies are needed.

Barriers for small farmers

Some 75% of the farmers in developing countries have less than 5 Hectares of land and a yearly income of US$ 300 to US$ 800. A single disastrous crop failure can turn them into landless laborers or send them into the urban ghetto. They have no access to technology like tractors or harvesters. Irrigation pumps to pump from rivers or shallow wells cost US$ 300 or more. Motorized pump options for wells deeper than 8 m. costs US$ 800 or more. Small farmers normally cannot afford these technologies, and subsidies on wells and irrigation schemes often have not worked, or only reached bigger farmers. In general technology designers do not see small farmers as customers.

Low cost irrigation from shallow wells

However , the potential of small farmers to increase production by irrigation is enormous and using the right varieties and technologies, food production worldwide could be tripled, but as Paul Polak of IDE states:

"The most important barrier is lack of affordable irrigation technology".

Modern irrigation technology has been developed for the middle and high income farmers that have enough land. However there are promising developments for farmers with a few acres. For instance in Bangladesh a hand sludged well and a "Treadle pump", (pedal powered) cost US$ 20. With low cost of labor and rising cost of fuel, irrigating with this Treadle pump is much cheaper than with a motor pump. The organization IDE informs that more than one million farmers already irrigate rice or dry season vegetables with Treadle pumps and so earn an additional income of US$ 100 annum year, adding a total of US$ 100 million to the national income of Bangladesh.

Low cost irrigation from deep wells

The Treadle pump works in areas with water levels less than 8 meters below ground level but for deeper wells, a different pump technology is needed. For wells down to 70 m. the Rope pump is now considered a good option. Similar to the Treadle pump the Rope pump has low production costs and is easy to install and maintain. Because of its high pumping capacity (40 l/min. for a 10 m. well) the use of the hand Rope pump for small scale irrigation is increasing. For larger scale irrigation, Rope pump models "powered by" wind, horse, pedals or motors have capacities of 60 to 180 liters per minute. From wells of 10 to 40 meters deep, 2 to 0.5 Hectares can be irrigated with furrow irrigation. If the newer low-pressure drip irrigation technology is used irrigated areas could be doubled.

The green revolution has tripled world grain production using fertilizers and irrigation but has now come to limits like availability of water, salinity, unsustainable mechanization, energy consumption, etc. 1 Billion people still experience hunger and the world population is growing, so new approaches and technologies are needed.

Barriers for small farmers

Some 75% of the farmers in developing countries have less than 5 Hectares of land and a yearly income of US$ 300 to US$ 800. A single disastrous crop failure can turn them into landless laborers or send them into the urban ghetto. They have no access to technology like tractors or harvesters. Irrigation pumps to pump from rivers or shallow wells cost US$ 300 or more. Motorized pump options for wells deeper than 8 m. costs US$ 800 or more. Small farmers normally cannot afford these technologies, and subsidies on wells and irrigation schemes often have not worked, or only reached bigger farmers. In general technology designers do not see small farmers as customers.

Low cost irrigation from shallow wells

However , the potential of small farmers to increase production by irrigation is enormous and using the right varieties and technologies, food production worldwide could be tripled, but as Paul Polak of IDE states:

"The most important barrier is lack of affordable irrigation technology".

Modern irrigation technology has been developed for the middle and high income farmers that have enough land. However there are promising developments for farmers with a few acres. For instance in Bangladesh a hand sludged well and a "Treadle pump", (pedal powered) cost US$ 20. With low cost of labor and rising cost of fuel, irrigating with this Treadle pump is much cheaper than with a motor pump. The organization IDE informs that more than one million farmers already irrigate rice or dry season vegetables with Treadle pumps and so earn an additional income of US$ 100 annum year, adding a total of US$ 100 million to the national income of Bangladesh.

Low cost irrigation from deep wells

The Treadle pump works in areas with water levels less than 8 meters below ground level but for deeper wells, a different pump technology is needed. For wells down to 70 m. the Rope pump is now considered a good option. Similar to the Treadle pump the Rope pump has low production costs and is easy to install and maintain. Because of its high pumping capacity (40 l/min. for a 10 m. well) the use of the hand Rope pump for small scale irrigation is increasing. For larger scale irrigation, Rope pump models "powered by" wind, horse, pedals or motors have capacities of 60 to 180 liters per minute. From wells of 10 to 40 meters deep, 2 to 0.5 Hectares can be irrigated with furrow irrigation. If the newer low-pressure drip irrigation technology is used irrigated areas could be doubled.