How to make a Rope pumps

|

Drawings

Download technical drawings of the three different hand Rope pump models: Wheel

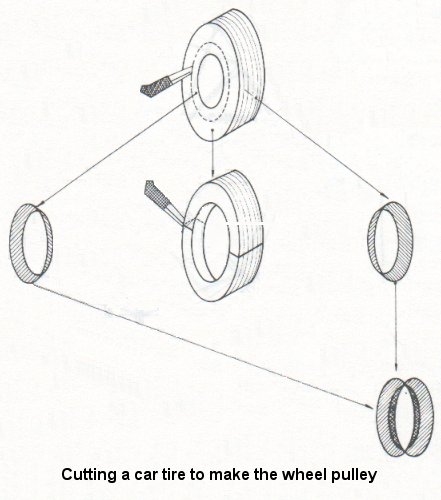

Make the wheel out of the inner rings of (used) car tires. Cut rings of 5 cm and put them together with clamps. Tires of 18 or 20 inch can be used, but tires of 14 or 15 inch function well, take less volume and are easier to work with.. Blockage system

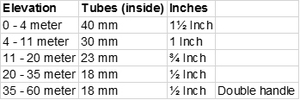

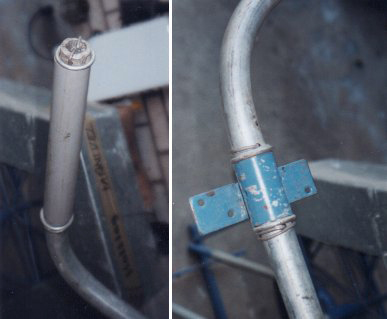

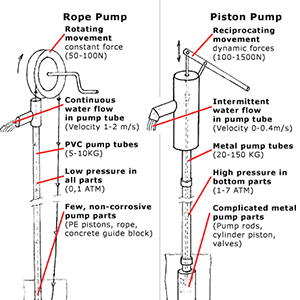

To avoid the handle from turning back when pumping is stopped, a blocking system should be included. For Models P this can be a rope holding the handle. For Models A the most efficient system is to mount it at the "outside part" of the wheel. Axle/ Handle The handle radius (eccentricity) depends on the diameter of the wheel and should be calculated as follows: ½ wheel diameter + 1 inch (Example: 14 inch tire, 8 inch handle radius) Preferably use galvanized tube of ¾ inch. Make angles of 60 degrees instead of 90 (easier to bend, safes material) Ball bearings can be used but bushings, made of a piece of 1 Inch galvanized tube, are more durable, easier to mount and much cheaper! They do not rust and if lubricated in time they do not wear out! Bushings mounted in 50.000 pumps prove that it works! (in case of deeper wells, ball bearings may be considered) Rising main tubes Since pressure in the rising main is low, the tubes can be the cheap low pressure type. Diameter of the tubes depends on total elevation and is based on 50 Watts, the power that women and children can exercise over a longer period. At the top, (the discharge and outlet) the tube diameter should be double the diameter of the rising main tube. The discharge tube should be fixed to the pump structure or another fixed point.

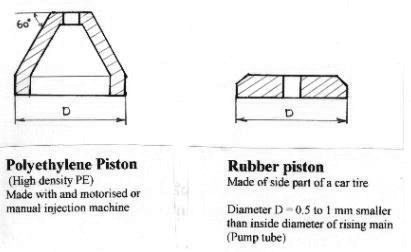

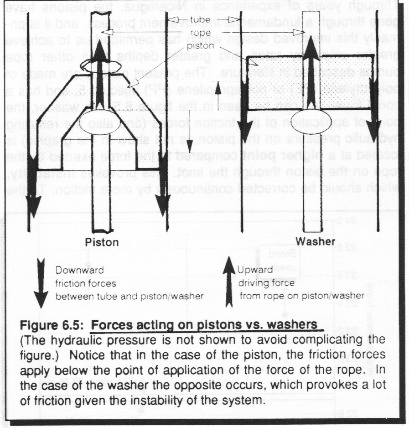

Pistons Pistons can be made of rubber, for instance out of the side part of an old car tire. Thousands of Rope pumps in Latin-America and Africa use this. Also leather or wood has been tried with less success. Pistons made of high-density polyethylene (HDPE) are efficient and easy to make standard sizes. PE pistons can be made by a motor powered extruder or a US$ 50 hand press. Pistons can be fixed to the rope by knots or melting a piece of rope on both sides of the piston. Rope

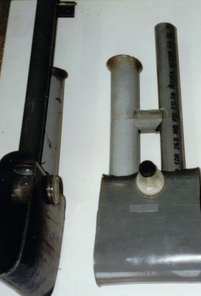

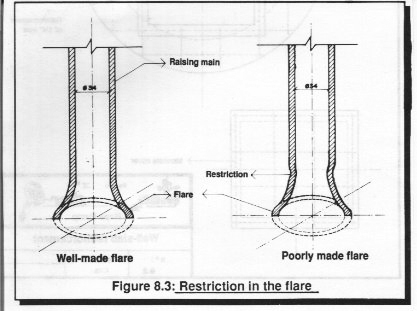

Rope used has to be 5 to 6 mm. Nylon is strong but also tends to "slide". Polypropylene rope gives better results. For wells deeper than 35 meter, thicker rope should be used. See video at the bottom. Guide box The guide box is an important part. The diameter of the "return tube" is bigger than the tube of the rising main and both should be well aligned and open at the end ("flared") to reduce the friction of the rope at this point. As "turning part" a glazed ceramic piece can be used or a small glass bottle, filled with cement. See video at the bottom. Ergonomic aspects

To generate maximum power for pumping, the height of the axle should be a few cm. higher than the belly button of the person pumping. This often requires a pump platform. Make sure this is done at the installation since experiences indicate that afterwards this will be "forgotten"! Maintenance Adjusting the tension of the rope when needed (should be just loose). Lubricate the bushings every 2 weeks or when needed adding a few drops of (new!) car oil. Do not use used oil (if car oil is not available use cooking oil). See video and picture at the right. |

Related videos

|

|

|

|

|